The Sea Dragon - Bowmore

Bowmore is a name deeply familiar and beloved among whisky enthusiasts. However, this, the oldest whisky distillery on Islay, has never been one of my favourite distilleries. The reasons are simple: I started exploring whisky relatively late, so I haven’t tasted many Bowmore expressions. Additionally, early on, I was heavily influenced by peaty flavours and felt that Bowmore, with its approximately 25ppm phenol level, wasn’t “authentic” enough. I used to believe that peat Islay whisky should deliver a punch with every sip to truly embody the “Islay flavour.”

But I was wrong.

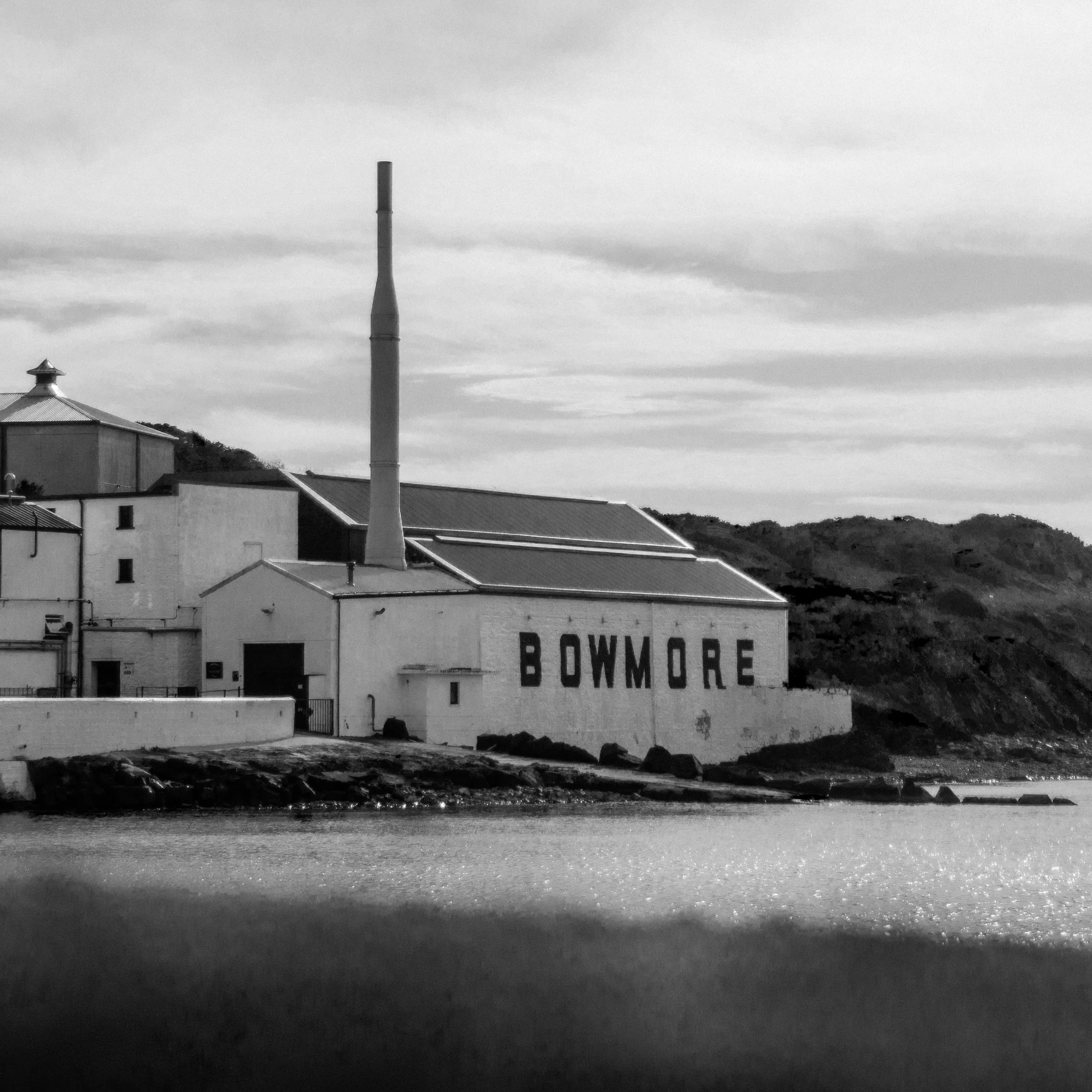

In traditional Scottish Gaelic, Bowmore, or Bogh Mòr, means “The Big Bend,” referring to the large bay where the distillery is located, also the heart of Islay’s town centre. The story begins with the 1725 “Malt Tax Riots.” At the time, the British Empire, recently unified, faced financial pressures from wars with France and colonial expansion. To fund these, the government decided to impose a tax on Scottish barley, aiming to standardize taxation across England and Scotland. Though the tax in Scotland was half that of England, essentials like beer, bread, and whisky faced steep price hikes, sparking widespread discontent among Scots. On June 23, 1725, riots erupted in Hamilton, Scotland, and spread across the region.

Daniel Campbell, a Member of Parliament representing the Clyde region (modern-day Glasgow), voted in favour of the tax bill, which led to his Glasgow residence being burned down by an angry mob. Ironically, this “Scottish traitor” received £9,000 in compensation from the government. In 1726, he used this money to purchase the entire island of Islay.

In 1766, David Simson, a local farmer and merchant, moved from Kilarrow to the newly established village of Bowmore, built by Daniel Campbell’s grandson, another Daniel Campbell. Simson leased a plot near the coast, and in 1779, Bowmore was officially founded, making it the second-oldest recorded whisky distillery in Scotland. It’s said that the Simson family had been producing illicit whisky on the land for over a decade before the distillery’s official establishment, marking the beginning of its legendary story.

Interestingly, there’s no consensus online about Bowmore’s founder. Some sources name John Simpson, others John P. Simson, and still others David Simpson. Curiously, while Bowmore’s official website recognizes David Simson and even released an expression named after him in 2020, the nameplates on the distillery’s washback read “Simpson,” adding to the mystery.

In 1837, the German-descended brothers William and James Mutter acquired Bowmore. James Mutter was, at the time, the vice-consul for the Ottoman Empire, Portugal, and Brazil in Glasgow. The Mutter family reportedly introduced several innovations, most notably a small iron steamship used to transport barley and coal from the mainland and deliver whisky to Glasgow for sale. Perhaps due to its refined flavour or some political connection, in 1841, Bowmore sold an entire cask of whisky to Windsor Castle, the British royal residence.

In 1887, ownership passed to the Sherriff family from Campbeltown, and John Bell Sherriff renamed the distillery the Bowmore Distillery Company. However, just three years later, the distillery went bankrupt. Over the next three decades, from 1892, it reportedly changed hands multiple times among London-based investors. In 1925, the Sherriff family regained control, renaming it Sherriff’s Bowmore Distillery. For the 15 years leading up to World War II, Bowmore enjoyed significant success.

In 1940, as World War II raged, Nazi Germany’s air raids on Britain prompted the Royal Air Force (RAF) to requisition Bowmore as a seaplane base and supply station, halting distillery operations for most of the war. In 1950, William Grigor & Sons Ltd. from Inverness acquired Bowmore, followed by Stanley P. Morrison in 1963, who renamed it Morrison’s Bowmore Distillery, Ltd. During this period, the distillery expanded to four stills and established one of Scotland’s first visitor centre. In 1980, Queen Elizabeth II visited, marking the first time a British monarch visited a Scottish whisky distillery.

In 1989, Japan’s Suntory acquired a stake in Morrison Bowmore, fully taking over in 1994.

In terms of production, Bowmore’s equipment setup is notably traditional. The 2+2 still configuration has been retained since the Morrison Bowmore era. The water source comes from the River Laggan, about seven miles south of the distillery. Bowmore still operates a three-tier malting floor, with each tier capable of processing around 14 tons of barley. For the first 24 hours, the soaked barley rests undisturbed on the floor, then is turned every four hours around the clock. Each malting batch takes about six days to complete before being dried in the distillery’s kiln to halt germination, locking in the sugars needed for whisky production.

The drying process involves 10 hours of smoking with peat sourced from Islay’s Gartbreck peat bogs, followed by 34 hours of hot air drying, producing malted barley with a phenol level of 25–30ppm. During a visit to the kiln room, though empty, I was captivated by the lingering, intoxicating peat aroma. In the early 1990s, Bowmore introduced a waste heat recovery system, redirecting heat from barley drying to supply the Mactaggart Leisure Centre (a former distillery warehouse, converted in 1991) with hot water for its community swimming pool, allowing year-round swimming for Islay residents.

Staff noted that while 80% of Islay’s land is covered by peat bogs (causing the island’s dramatically undulating roads), peat regenerates at a slow rate of just 1mm per year. To prevent over harvesting and protect the local ecosystem, Suntory launched the Peatland Water Sanctuary initiative in 2021. Bowmore reduced its peat consumption from 18 tons per week to just 3 tons. Currently, only 25% of the distillery’s barley is malted in-house, with the rest sourced from Simpson’s, a major barley supplier in Inverness, using Highland peat, which differs in flavour from Islay’s local peat.

The processed barley is sent to Bowmore’s iconic Porteus milling machine, in use since 1966 and painted a striking wine-red. The grist is milled to a standard 1:2:7 ratio and transferred to an 8-ton capacity semi-lauter stainless steel mash tun, covered with a copper lid, for mashing. In the mash house, what caught my attention most were two massive copper “water kettles” leaning against the wall near the entrance. These are essentially water tanks for supplying and recycling hot water during mashing—a common feature in distilleries but rarely made of copper or displayed so prominently. Initially, I mistook them for an oddly designed mash tun or some unique vessel.

The resulting wort is transferred to six 40,000 litres Oregon pine washbacks for fermentation. After 72 hours (though some sources mention both 48 and 72 hours fermentation periods), an 8% ABV wash is produced and sent for distillation. Each washback bears a nameplate honoring former owners. The distillery uses a classic 2+2 still configuration with traditional Scottish onion-shaped stills. The two wash stills, each with a 30,940 litres capacity, produce a 22% ABV low wine. The two spirit stills, with capacities of 14,637 litres (No. 1) and 14,750 liters (No. 2), have slightly elongated necks and upward-angled lyne arms to increase reflux and remove impurities. The second distillation yields a spirit at 79% ABV, with 79–74% as the heads, below 61% as the tails, and 61–74% as the heart, resulting in a new make spirit of approximately 68.8% ABV. Bowmore’s annual production is around 2.2 million litres.

As for the legendary Bowmore No. 1 Vaults, I must apologize - having only joined the basic tour, I didn’t get to explore the warehouse or touch the casks. My interest in this part is limited, but I know the angel’s share in the vaults is around 1%, and it houses high-age sherry and bourbon casks, among other treasures. Most of Bowmore’s casks, however, are stored in Glasgow, where new make spirit is typically sent for filling and maturation.

Finally, I asked a question many would find intriguing: “Why did Bowmore produce ‘soapy’ whiskies in the 80s and 90s?” According to distillery staff, during the challenging times for the Scotch whisky industry in the 1980s and 90s, Bowmore cut costs while maintaining production by shortening various processes. Reduced fermentation times produced more ester compounds with rose, lavender, and waxy soap-like notes. Faster distillation widened the heart cut, including more tail spirit containing fatty, soapy compounds. Poor cask management at the time also meant barrels failed to impart desired flavours or filter out off-notes, allowing these soapy characteristics to persist in the matured whisky. For Bowmore, these perfumed, soapy expressions are a dark chapter in its history. By the late 1990s, improved processes and higher standards eliminated these soapy notes, though they remain a quirky favourite among some enthusiasts.

Having learned about the distillery’s history and tasted more of its expressions, I’ve slowly come to appreciate (and am still learning to appreciate) Bowmore’s finesse and elegance. I hope to revisit the distillery and taste more of its older expressions in the future!